A messy, inefficient packing process can slow down your entire production line. This one machine might be your answer.

A case packer is a secondary packaging machine that automatically packs products into cases or boxes, making your packaging process faster, safer, and more consistent.

If you’re a manufacturer or trading company looking to optimize end-of-line packaging, this machine deserves your attention. Let’s explore what a case packer actually does and why it matters.

What does a case packer do?

When products are piling up and manual packing just can’t keep up, what do you do?

A case packer groups products and places them into pre-formed cases, sealing them for shipment or storage. It replaces manual labor and increases efficiency.

How does it pack products so quickly and neatly?

A case packer typically follows this process:

- Collating: It arranges individual items in a specific order.

- Loading: It picks up and inserts the group into an open case.

- Sealing: It closes the case using tape or glue.

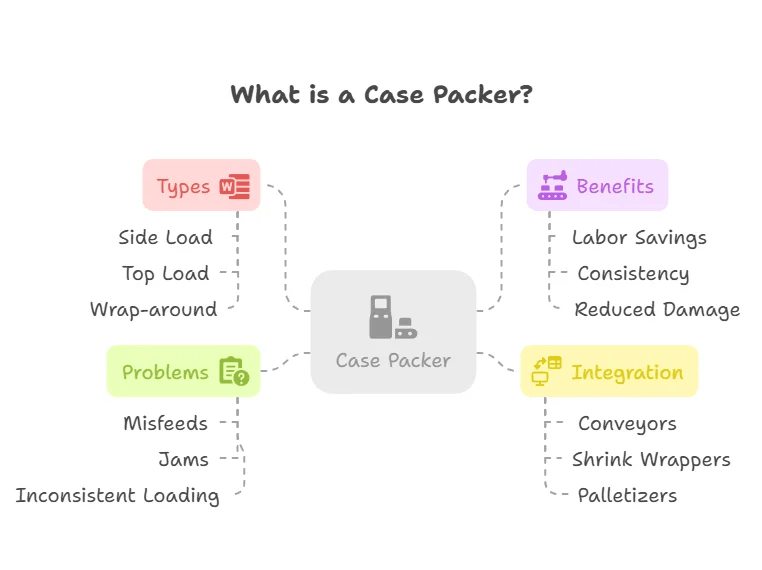

There are different types based on orientation:

| Case Packer Type | Product Orientation | Best For |

|---|---|---|

| Side Load | Horizontal | Cans, jars, small boxes |

| Top Load | Vertical | Bottles, cartons, fragile items |

| Wrap-around | Encloses the product | High-speed, uniform products |

I’ve seen customers struggle with inconsistent packing speeds. When they switch to an automatic case packer—especially from Hannpro—they notice immediate improvement in both productivity and quality.

Why do manufacturers need case packers?

Manual packing is slow, inconsistent, and unsafe.

Manufacturers use case packers to improve packaging speed, reduce labor costs, and avoid repetitive strain injuries for workers.

Is automation really worth the investment?

Here’s why most of my clients consider it essential:

1. Labor savings add up

When you replace 2-3 workers per shift, the savings over a year cover the machine’s cost.

2. Consistency improves brand image

A tightly packed, perfectly sealed box looks professional. That matters when your product hits the shelves.

3. Less damage, fewer returns

Products don’t shift or get damaged during transport. The snug fit of cases from a machine reduces movement and improves stability.

Many of my customers also appreciate that Hannpro machines are modular and scalable, which means they grow with your production line.

What types of products can a case packer handle?

Some machines are built for bottles. Others for boxes. But some do both.

Case packers can handle bottles, cans, cartons, pouches, and even fragile items, depending on the design.

Choosing the right match for your product

Every product has a shape, a weight, and a stacking limitation. Matching those to the right machine is key.

| Product Type | Ideal Packer Type | Notes |

|---|---|---|

| Glass Bottles | Top Load | Fragile, needs gentle handling |

| Cartons | Wrap-around | Uniform size is best |

| Pouches | Side Load | Requires tight grouping |

| Aerosol Cans | Side Load | Needs secure placement |

At Hannpro, we often advise customers based on their specific product packaging flow. It’s not just about fitting items in a box—it’s about keeping that flow smooth and fast.

What’s the difference between semi-auto and full-auto case packers?

Some businesses don’t need full automation. Others can’t grow without it.

Semi-automatic packers require some human intervention, while fully automatic machines handle everything from forming to sealing without manual input.

Which one should you choose?

Semi-Automatic

- Lower initial cost

- Good for small batches

- Operators still needed

Fully Automatic

- High speed

- 24/7 operation

- Minimal labor

If you’re just starting out, you might go semi-auto. But if you’re scaling fast, a fully automatic Hannpro case packer can support long-term growth.

How much does a case packer cost?

Many buyers worry about cost—but few think about long-term value.

A case packer can range from $15,000 to over $100,000, depending on speed, configuration, and automation level.

What affects the price?

| Factor | Impact on Cost |

|---|---|

| Automation level | Full-auto costs more |

| Speed | Faster machines = $$$ |

| Product type | Complex shapes = higher |

| Customization | Increases total price |

At Hannpro, we offer models across the spectrum—our goal is to match your budget with your need. We’re always transparent about pricing and lifetime ROI.

Can a case packer integrate with my existing line?

One machine is helpful—but many machines working together? That’s power.

Yes, case packers can integrate with conveyors, shrink wrappers, and palletizers for a full end-of-line automation solution.

Building a smooth, connected packaging system

When all machines talk to each other, the result is beautiful: fewer stoppages, faster throughput.

We help our clients design lines where the case packer acts as a bridge between primary packaging and palletizing. It keeps everything in sync.

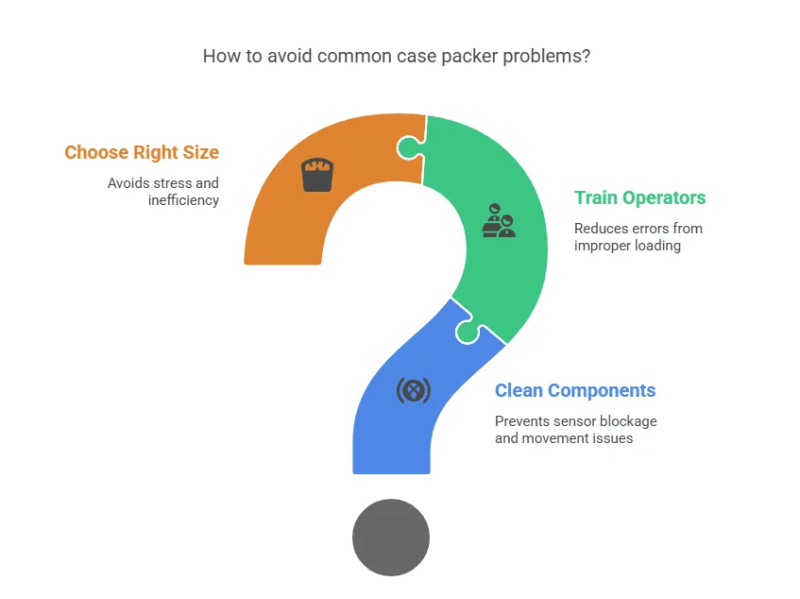

What are common problems with case packers?

Even the best machines can hit snags. The key is knowing what to watch for.

Misfeeds, jams, or inconsistent loading are the most common problems—but they’re easy to fix with training and preventive maintenance.

How to avoid headaches

1. Keep components clean

Dust and debris block sensors or clog movement.

2. Train your operators

Many errors come from improper loading or missed steps.

3. Choose the right size machine

Overloading or underloading can cause stress or inefficiency.

At Hannpro, we provide onboarding training and maintenance guides to avoid these issues.

Conclusion

Case packers make secondary packaging faster, safer, and more reliable—no matter your product or scale.

FAQs

1. Can one case packer handle multiple product sizes?

Yes, with changeover kits or adjustable settings, many machines can pack different sizes.

2. How long does setup take for a new case packer?

Typically 1–3 days including training, depending on system complexity.

3. Are case packers hard to maintain?

No. With basic training, daily checks and weekly cleaning, they’re easy to manage.

4. Can Hannpro customize a case packer for my needs?

Absolutely. We tailor machines based on product, box type, and speed goals.

5. Does Hannpro offer after-sales support?

Yes. We offer remote guidance, spare parts, and on-site service if needed.

6. What materials work best with case packers?

Corrugated cardboard boxes are ideal. Machines work best with consistent, quality materials.