Pain. Struggle. Waste. These are the feelings when packaging isn’t efficient.

Secondary packaging machines can use cardboard, shrink film, stretch film, trays, paperboard, and corrugated materials—each chosen based on product type and transport needs.

If you’re confused about what materials your secondary packaging machine can handle, you’re not alone. In this article, I’ll help you understand what options exist, how to choose the right one, and why it matters. Stick around—we’re about to unpack it all.

What types of materials are most commonly used?

Packaging errors cost money. Using the wrong material can lead to product damage or higher freight costs.

The most common materials used are corrugated cardboard, shrink wrap, stretch film, and paperboard, depending on the product’s shape, size, and transport requirements.

Corrugated cardboard: Reliable and reusable

Corrugated cardboard is the go-to for many secondary packaging applications. It’s tough, recyclable, and offers good protection. It’s also ideal for products that are heavy or fragile. We often use this when customers ask for sturdy, stackable boxes. It also allows for easy branding.

Shrink film: Tight and efficient

Shrink film is used to wrap products tightly together using heat. It’s good for items that are not too fragile. It holds everything in place, reduces tampering, and gives a clean look. At Hannpro, we often suggest this for bottled products or lightweight retail items.

| Material | Best For | Pros | Cons |

|---|---|---|---|

| Corrugated box | Heavy or fragile products | Durable, printable | Bulky, not waterproof |

| Shrink film | Bottles, multipacks | Space-saving, cost-efficient | Needs heat, not very strong |

| Stretch film | Pallet loads | Fast application, flexible | Less secure than shrink |

| Paperboard | Light consumer goods | Lightweight, printable | Low strength |

Why does the material choice matter?

Wrong materials can cause returns, damage, or waste. That means lost money and unhappy customers.

The right material protects your products, saves costs, and keeps your operations smooth.

It’s not just about protection—it’s about profit

Every packaging material has a different strength, weight, and cost. Choosing a poor fit can mean higher logistics costs. For example, using thick cardboard for lightweight items increases weight unnecessarily. On the flip side, using thin film for heavy goods may cause tearing. At Hannpro, we work with clients to test materials and find a balance between strength, cost, and speed.

Compliance and brand image matter too

Materials also impact how your products look and feel. Retailers and end customers notice. Some industries require recyclable or food-safe packaging. You can’t afford to ignore this. Choosing eco-friendly options like recycled cardboard can also enhance your brand.

| Impact Area | Material Decision Role |

|---|---|

| Logistics cost | Heavier materials increase shipping weight |

| Product safety | Poor material may cause damage |

| Customer impression | Clean packaging builds trust |

| Sustainability | Recyclable options reduce footprint |

How do I choose the best one for my product?

Choosing without testing leads to mistakes. You need a system, not a guess.

To choose the best material, consider product weight, shape, fragility, storage conditions, and customer requirements.

Product profile is the starting point

First, identify your product’s weight, dimensions, and whether it’s fragile or irregularly shaped. We often see lightweight products get over-packaged and heavy goods under-protected. This mismatch causes waste or returns.

Match machine capabilities with materials

Not every secondary packaging machine supports every material. For example, your cartoning machine may not handle stretch film. At Hannpro, we build machines that can work with multiple materials, but we always advise customers to align product needs with machine capability. Always ask for a material compatibility checklist from your supplier.

Customer and retailer needs shape decisions

Sometimes it’s not about what you prefer, but what your customers or retailers demand. Supermarkets might require barcode visibility or certain tray shapes. E-commerce sellers may prefer lightweight packaging to save on fulfillment costs.

| Decision Factor | Questions to Ask |

|---|---|

| Product size & shape | Is it fragile? Odd-shaped? Sturdy? |

| Transport method | Palletized? Air freight? Long-distance? |

| Storage environment | Cold chain? Humid conditions? Dry warehouse? |

| Customer expectations | Retail-ready? Minimalist? Branded? |

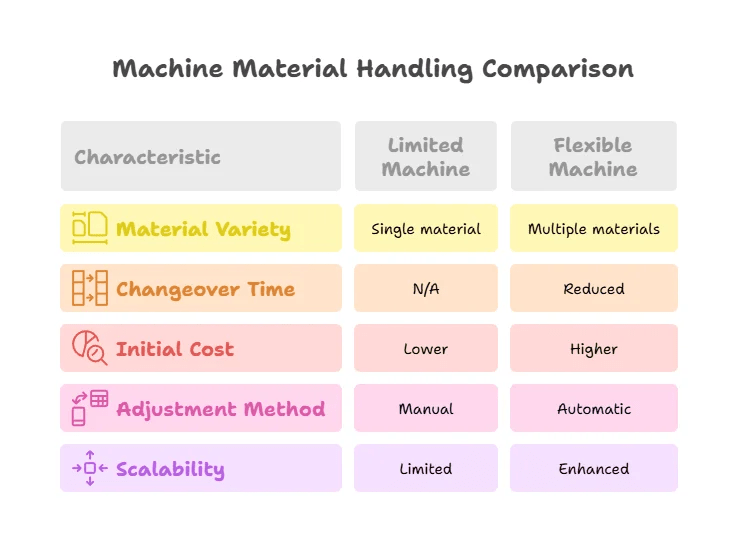

Can one machine handle multiple materials?

Using just one material limits your flexibility. But switching too often also wastes time.

Yes, some advanced secondary packaging machines can switch between materials like shrink film, trays, and cardboard—if designed for flexibility.

Don’t assume—check the spec sheet

Many clients ask us if their existing machine can just “switch” materials. Often, the answer is no—unless it was built with that in mind. Hannpro machines are designed to handle different materials, but we still recommend defining primary and secondary materials to streamline changeovers.

Auto-adjusting tech is the game changer

Modern machines can detect material thickness and adjust sealing or wrapping speed automatically. This tech helps reduce setup time and human error. But it costs more upfront. We’ve helped many clients invest in this tech when they scale or diversify their product line.

| Machine Flexibility Feature | Beneficiar |

|---|---|

| Auto-calibration | Speeds up changeovers |

| Multi-feed systems | Allows different material input |

| Programmable memory | Stores settings for each material type |

| Tool-less changeover | Fast, operator-friendly adjustments |

Conclusão

Material choice in secondary packaging affects cost, protection, and customer experience—get it right, and your operation flows smoothly.