Packing products manually is slow, expensive, and prone to errors. If your business is still relying on hand-packing, you’re likely losing time and money.

An automatic 카토너 improves efficiency, reduces labor costs, and ensures precise, professional packaging. Investing in automation can increase production speed, minimize waste, and enhance product presentation.

For businesses aiming to scale up, automation is no longer an option—it’s a necessity. Let’s dive deeper into why choosing an automatic cartoner, especially from 한프로, is the right decision.

What Are the Key Benefits of an Automatic Cartoning Machine?

손으로 포장하는 작업은 노동 집약적이고 일관성이 없습니다. 반복적인 작업을 인간 작업자에게 의존하면 비효율성과 오류가 발생하여 기업에 상당한 시간과 비용이 소요될 수 있습니다.

자동 상자 포장기는 사람의 실수를 없애고 생산 속도를 높이며 일관된 고품질 포장 경험을 제공하여 궁극적으로 생산성과 수익성을 높입니다.

더욱 빨라진 생산 속도

속도는 모든 생산 라인에서 중요한 요소입니다. 에이 수동 포장 과정 자동 상자 포장기는 인간의 지구력과 속도에 의해 제한되는 반면, 자동 상자 포장기는 지속적으로 작동하여 분당 수백 개의 상자를 포장합니다.

| 요인 | 수동 포장 | 자동 카토너 |

|---|---|---|

| 속도 | 5-20의 판지/분 | 60-300개의 판지/분 |

| 노동 의존도 | 높은 | 낮은 |

| 오류율 | 높은 | 최소한의 |

포장 속도를 높이면 기업은 추가 인력을 고용하지 않고도 증가하는 수요를 충족할 수 있습니다. 이는 더 높은 효율성과 더 큰 출력을 보장합니다.

일관된 품질과 정밀도

수동으로 포장하면 다양성이 발생합니다. 일부 상자는 잘못 접혀 있거나, 제대로 밀봉되지 않았거나, 라벨이 잘못 붙을 수 있습니다. 이러한 불일치는 브랜드의 평판을 손상시키고 제품 반품이나 리콜로 이어집니다.

자동 상자 포장기는 모든 패키지가 품질 표준을 충족하도록 정확하게 접히고 밀봉되고 라벨이 붙도록 보장합니다. 그 결과 고객 만족도를 높이는 균일하고 전문적인 느낌의 제품이 탄생합니다.

인건비 절감

인건비는 제조사에게 가장 큰 비용 중 하나이다. 수동 포장을 위해 직원을 고용하고 교육하는 데 비용이 많이 들 수 있으며 직원에게는 휴식, 감독 및 급여가 필요합니다.

자동 상자 포장기는 노동 의존도를 크게 줄여줍니다. 하나의 기계로 여러 작업자를 대체하여 급여 비용을 낮추고 인적 오류를 최소화할 수 있습니다.

자동 카토나이너는 어떻게 비즈니스 효율성을 향상합니까?

포장 공정의 비효율성은 생산 속도를 늦추고 폐기물을 늘리며 비용을 증가시킬 수 있습니다. 포장을 최적화하지 못하는 기업은 시장 수요를 충족하는 데 어려움을 겪는 경우가 많습니다.

상자 포장을 자동화함으로써 기업은 생산성을 향상하고 오류를 줄이며 손쉽게 운영을 확장할 수 있습니다.

재료 낭비 감소

Human workers often make mistakes when folding or sealing cartons, leading to wasted packaging materials. Automation ensures precision, minimizing material waste and reducing unnecessary costs.

| Waste Factor | 수동 포장 | 자동 카토너 |

|---|---|---|

| Misfolded Cartons | Common | Rare |

| Excess Material Usage | 높은 | 최소한의 |

| Error Corrections | Frequent | Almost None |

Reducing material waste also contributes to a more sustainable packaging process, which is increasingly important for eco-conscious brands.

Increased Output with Less Labor

For businesses handling high-volume orders, relying on human workers alone can lead to bottlenecks. Automation streamlines production, ensuring that orders are packed and shipped on time.

With an automatic cartoner, a single operator can oversee the process instead of multiple workers manually assembling cartons. This efficiency allows businesses to handle larger orders without expanding their workforce.

What Types of Automatic Cartoners Are Available?

Not all automatic cartoners are the same. Understanding the different types available can help businesses choose the right machine for their specific needs.

Cartoning machines come in two main types: horizontal and vertical. Each type is suited for different kinds of products and packaging requirements.

Horizontal vs. Vertical Cartoners

| Machine Type | Best for Packaging | Sealing Methods | Example Products |

|---|---|---|---|

| Horizontal | Bottles, tubes, sachets | Glue, tuck-in | Pharmaceuticals, food |

| Vertical | Powders, granular products | Glue, tuck-in | Cereals, coffee |

수평 상자는 상자에 쉽게 밀어 넣을 수 있는 제품에 적합하고, 수직 상자는 헐렁하거나 세분화된 제품에 더 적합합니다.

사용자 정의 옵션

많은 기업에서는 기계에 대한 특정 조정이 필요한 고유한 포장 요구 사항을 가지고 있습니다. Hannpro는 다양한 상자 크기, 밀봉 방법 및 공급 시스템을 수용할 수 있는 맞춤형 상자 포장 기계를 제공합니다.

맞춤형 솔루션을 선택함으로써 기업은 포장 프로세스가 생산 요구 사항에 완벽하게 부합하는지 확인할 수 있습니다.

포장 기계로 Hannpro를 선택하는 이유는 무엇입니까?

With so many options available, selecting the right cartoning machine supplier is just as important as choosing the machine itself. Not all manufacturers offer the same level of quality, reliability, and support.

Hannpro specializes in high-performance cartoning machines designed to improve efficiency, reduce costs, and meet diverse packaging needs.

Industry Experience

Hannpro has years of experience in designing and manufacturing cartoning machines for various industries. Our deep understanding of packaging challenges allows us to provide solutions that enhance production efficiency.

Advanced Technology

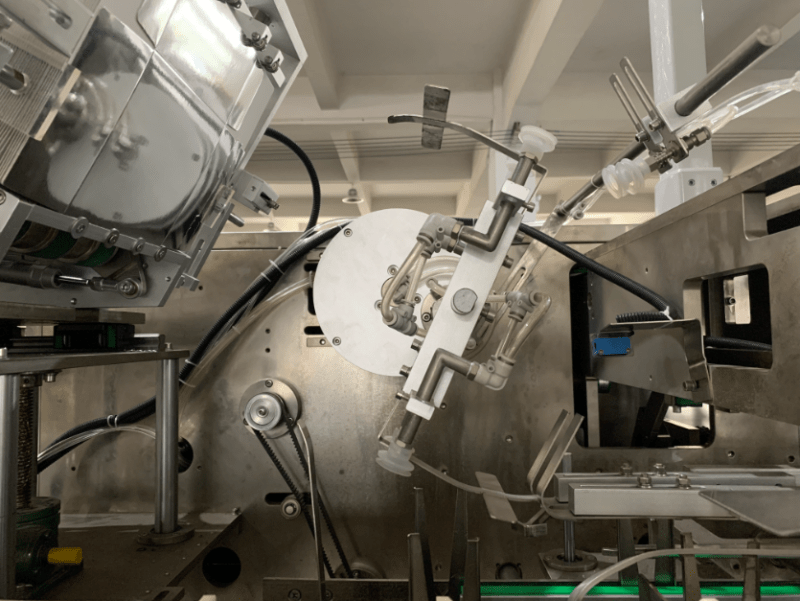

Our machines come with state-of-the-art features such as:

- Touch-screen controls for easy operation

- Automatic product feeding for seamless integration into production lines

- Error detection systems to prevent packaging defects

These features ensure that Hannpro’s cartoning machines deliver superior performance and reliability.

Dedicated Customer Support

Investing in automation doesn’t end with purchasing a machine. Proper installation, training, and maintenance are essential for long-term efficiency. Hannpro provides comprehensive after-sales support, including:

- On-site installation and training

- Regular maintenance services

- 24/7 customer support for troubleshooting

By choosing Hannpro, businesses can ensure smooth operations with minimal downtime.

What Industries Benefit the Most from Automatic Cartoning Machines?

Cartoning machines are used across multiple industries, providing automation solutions for different packaging needs.

| 산업 | Example Products | Benefits of Automation |

|---|---|---|

| 제약 | 약병, 블리스 터 팩 | 정확한 라벨링, 변조 방지 포장 |

| 음식 & 음료 | 스낵 상자, 시리얼 상자 | 위생적인 포장, 고속 생산 |

| 화장품 | 튜브, 크림병 | 우아한 포장, 최소한의 폐기물 |

| 소비재 | 치약, 생활용품 | 일관된 브랜딩, 인건비 절감 |

업종에 관계없이 대량의 일관된 포장이 필요한 모든 비즈니스는 자동화의 이점을 누릴 수 있습니다.

결론

자동 포장 기계를 선택하는 것은 포장 효율성을 향상하고 비용을 절감하며 제품 품질을 향상시키는 데 중요한 단계입니다. Hannpro는 기업이 운영을 원활하게 확장하는 데 도움이 되는 맞춤형 고성능 기계를 제공합니다.

If your goal is faster production, consistent quality, and long-term cost savings, investing in an automatic cartoning machine from Hannpro is the best decision.