Still spending hours manually packing each box?

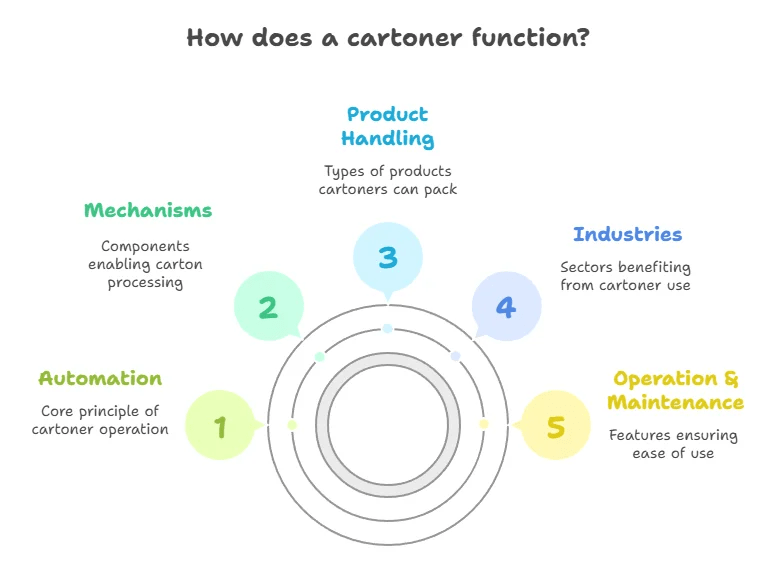

A cartoner is a packaging machine that folds cartons, inserts products, and seals them automatically—helping factories save time, labor, and reduce error rates. It’s crucial to understand the cartoner function before investing in automation.

Cartoners work like silent, efficient workers. In one motion, they open flat boxes, fill them with products, and seal them. If you’re in manufacturing or trading, this machine could change the way you handle packaging forever.

Let me walk you through exactly how it works, how it’s built, and what it can do for your business.

What is a cartoner and how does it function?

Manual packing slows you down and increases the chance of error.

A cartoner turns flat cardboard into fully packed boxes, using a series of mechanical steps like forming, loading, and sealing—all in one line. This is the core of the cartoner function and why it’s so efficient.

Types of Cartoners

| Type | Description | Best Use Cases |

|---|---|---|

| Horizontal Cartoner | Moves cartons sideways; product pushed in | Ideal for bar-shaped, flow-packed items |

| Vertical Cartoner | Product drops from top into carton | Suited for loose items like sachets or vials |

The type of cartoner you use depends on the shape and handling needs of your product. Horizontal models are great when products are fed automatically from upstream machines. Vertical cartoners work best when items are manually dropped or gravity-fed.

Step-by-step Function of a Cartoner

Here’s a deeper breakdown of how our Hannpro machines typically work, and how the cartoner function ensures smooth operation:

1. Carton Magazine Feeding

The machine stores a stack of flat cartons in a magazine. A vacuum suction cup or mechanical arm picks one flat carton and moves it to the forming station.

2. Carton Forming and Positioning

The machine then erects the flat carton into a box shape using side guides and pushers. Precision is key here—any misalignment affects downstream steps.

3. Product Loading

Products are pushed or dropped into the open carton. This can be done by mechanical pushers, robots, or even manually in semi-automatic setups.

4. Sealing

The machine then closes the flaps using glue (hot melt) or a mechanical tuck-in system. The choice depends on carton design and product security needs.

5. Discharge

The sealed carton is pushed onto an outfeed conveyor and sent to the next line—maybe shrink-wrapping or case-packing.

This whole cycle repeats rapidly, with some lines packing up to 200 cartons per minute. The timing of suction, pusher, flap closer, and conveyor must all work perfectly in sync. That’s where the precision of the cartoner function plays a key role.

What is the working principle of a cartoning machine?

Too much human error in your packaging line?

The core principle is automation: mechanical systems, pneumatic cylinders, and sensors work together to form, fill, and seal cartons efficiently. The cartoner function depends on this precise coordination.

Main Mechanisms at Work

| Function | Component Involved | Role |

|---|---|---|

| Carton Picking | Suction arm / rotary drum | Grabs flat carton from magazine |

| Carton Forming | Guide rails / erecting plates | Converts flat carton into box shape |

| Product Loading | Mechanical pusher / pick-and-place robot | Inserts product safely and accurately |

| Flap Closing | Glue nozzle or tucker arms | Seals carton depending on carton design |

| Outfeed | Conveyor belt / ejector | Transfers completed cartons |

Cartoning machines are controlled by PLCs (programmable logic controllers), which coordinate timing and motion. Each step in the cartoner function must respond instantly to sensors to avoid downtime or damage.

From my experience helping clients troubleshoot packaging lines, I’ve seen how important this timing is. A delay of just 0.2 seconds in flap closing can jam the whole system. That’s why we build every Hannpro machine with fine-tuned sensors and servo systems to ensure optimal cartoner function.

What kinds of products can be packed with a cartoner?

Think your product is too odd-shaped for automation?

Cartoners handle everything from toothpaste tubes to vials, cookies to cosmetics—making them versatile tools across industries. Understanding this wide cartoner function is essential for product planning.

Industries and Product Types

| Industry | Products Commonly Packed |

|---|---|

| Pharmaceuticals | Blister packs, bottles, ampoules |

| Food | Granola bars, tea bags, chewing gum |

| Cosmetics | Tubes of cream, facial masks, soap bars |

| Consumer Goods | Razors, batteries, detergent pods |

A key strength of modern cartoners—like those in the Hannpro product line—is adaptability. We often build machines with modular feeding systems. This lets our clients run several different SKUs with minor adjustments.

Let’s say you’re packing a tube of ointment with a leaflet. Our machines use leaflet inserters, glue dots, and barcode readers to handle this extra step automatically. That saves time and reduces mispacks while enhancing the overall cartoner function.

Are cartoners easy to operate and maintain?

Worried about hiring specialists to run complex machines?

Modern cartoners are user-friendly, with touchscreens, diagnostics, and auto-adjust features that make them easy to operate and maintain. These also optimize the long-term cartoner function.

Operating Features That Make a Difference

| Feature | Benefit |

|---|---|

| Touchscreen HMI | Easy setup and troubleshooting |

| Auto-adjustable rails | Fast changeovers between carton sizes |

| Servo motors | Precision movement with fewer parts |

| Self-cleaning guides | Reduces downtime due to dust or jamming |

We design Hannpro machines with operators in mind. Most settings can be adjusted from the screen—no tools required. Plus, visual alerts and safety doors prevent accidents.

Preventive maintenance is also simple. Our machines come with logs and alarms that remind users to clean, oil, or check components. This helps keep uptime high and the cartoner function stable.

Training a new operator usually takes one or two days. We also offer video tutorials and remote support if needed.

Conclusion

Cartoners save time, reduce labor, and boost efficiency. A smooth cartoner function is key to any modern packaging line.

FAQs

1. Can I pack multiple items in one carton using a cartoner?

Yes. Most machines allow multi-product loading with additional feeding units. This advanced cartoner function helps with bundling.

2. What kind of glue is used in glued flap sealing?

Hot melt glue is standard. It’s quick-drying, clean, and supports strong cartoner function.

3. Are cartoners compatible with upstream/downstream automation?

Absolutely. Cartoners integrate well into full lines, enhancing total packaging system function, especially the cartoner function.

4. How long does it take to switch between products?

With tool-free designs, switchovers take 10–15 minutes. Our machines at Hannpro are optimized for quick transitions that maintain consistent cartoner function.

5. Do I need a technician to set up the machine every time?

Not for daily operation. We train your staff during installation. Most changeovers are intuitive and support steady cartoner function.

6. Can a cartoner handle printing or coding?

Yes. We can add printers, coders, or labelers to the line. These integrate seamlessly with the cartoner function for full traceability.