Some people think flow wrappers are only used for primary packaging. But when used to group products together, they become something much more powerful.

A flow wrapper is a machine that wraps one or more items in film. When used to bundle multiple products, it becomes a form of secondary packaging.

This difference matters if you’re building a packaging line. I’ve helped many clients understand when flow wrapping steps beyond just protecting a single product—and starts organizing, grouping, and prepping for retail.

What is flow wrap packaging?

People often ask me, “Is flow wrap just for snacks?” It’s much more than that.

Flow wrap packaging is a flexible, horizontal sealing method that can be used for both primary and secondary packaging—depending on how it’s applied.

Primary vs. Secondary: Understanding the dual role

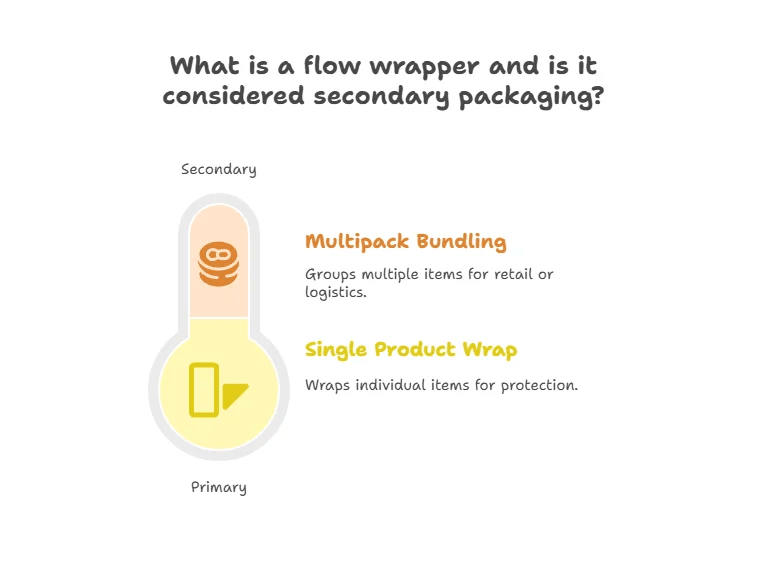

Flow wrap isn’t locked into one function. It depends on the context. When wrapping a single chocolate bar, it’s primary. But when wrapping six bars into one unit? That’s secondary.

Flow wrap’s dual usage:

| Usage Context | Type of Packaging | Example |

|---|---|---|

| Single product wrap | Primary packaging | Candy bar, surgical gloves |

| Multipack bundling | Embalaje secundario | 6 snack bars in one flow wrap |

At Hannpro, we offer flow wrappers designed for both jobs. Whether you’re sealing one item or building a bundle, we help you choose the right setup.

Is a flow wrapper considered secondary packaging?

It depends—are you wrapping one item or grouping many?

Yes, a flow wrapper is considered secondary packaging when used to bundle multiple items into a single unit for retail or logistics.

Multipacks, kits, bundles: That’s secondary packaging

Many of our clients use flow wrap to make kits. Think of cosmetic sets, snack variety packs, or even grouped medicine packs. In these cases, flow wrapping is not the first layer—it’s the layer that holds several units together.

A closer look at secondary use cases:

| Product Type | Primary Packaging | Secondary (Flow Wrap) Example |

|---|---|---|

| Snack bags | Individual flow wraps | Flow-wrapped 6-pack |

| Blister packs | Plastic tray | 3 trays in a flow-wrapped kit |

| Travel cosmetics | Bottles | Flow wrap around 4 items |

When clients at Hannpro want to automate this bundling step, we guide them toward flow wrap systems with proper feeding, aligning, and grouping systems.

What kind of products use flow wrap for secondary packaging?

You’d be surprised how many industries use flow wrap to bundle.

Flow wrapping is often used in secondary packaging for food multipacks, medical kits, household items, and promotional retail packs.

Secondary flow wrap in action

Flow wrapping is clean, fast, and cost-effective. It’s perfect for creating retail-ready bundles or for grouping items for wholesale distribution.

Examples from different industries:

| Industry | Secondary Flow Wrap Example |

|---|---|

| Food | 5 cookie packs in 1 retail wrap |

| Pharma | 3 blister cards in a patient kit |

| Household Goods | 2 soap bars bundled together |

| Toys | Gift sets or character bundles |

One of our customers, a snack company, switched from shrink bundling to flow wrap. The result? Faster lines, neater appearance, and lower film costs. At Hannpro, we helped redesign their secondary packaging to suit flow wrap’s strengths.

How do flow wrappers work for multipacks?

Some think flow wrappers only handle one product at a time. That’s not true at all.

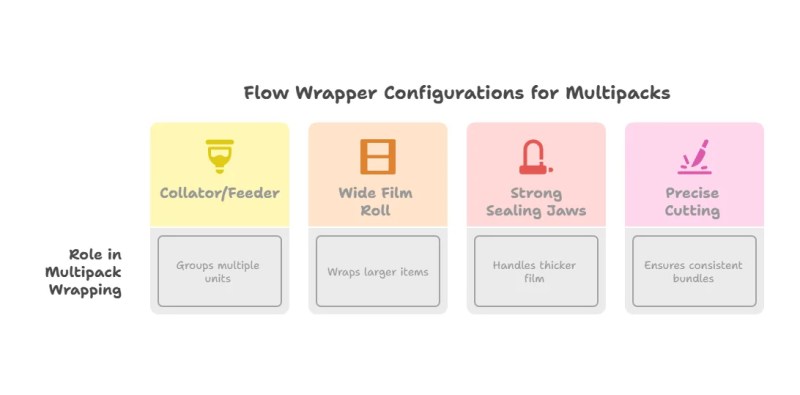

Flow wrappers for secondary packaging are often customized with infeed grouping systems, allowing them to wrap multiple items into one pack.

Flow wrapper setup for bundling

When wrapping multipacks, the machine is set to receive grouped items—manually or through an automated collator. The rest of the process is like single-item wrapping, but bigger and more structured.

Machine configuration for secondary tasks:

| Feature | Role in Multipack Wrapping |

|---|---|

| Collator/feeder | Groups multiple units |

| Wide film roll | Wraps larger or bulkier items |

| Strong sealing jaws | Handles thicker film + grouped load |

| Precise cutting | Ensures consistent, sealed bundles |

We configure Hannpro machines with optional feeders and format changers. This helps clients switch between single and multi-item wrapping without changing equipment.

Why use flow wrapping for secondary packaging?

You might ask: Why not just use a box? Why wrap bundles?

Flow wrap is faster, cheaper, and often more visually appealing than cartons or shrink bundling for grouped items.

Flow wrap advantages in secondary roles

Flow wrap doesn’t need heating tunnels like shrink wrap. It uses less material than cartons. And with printed film, it still offers high branding impact.

Benefits over other methods:

| Secondary Method | Speed | Material Cost | Branding Potential |

|---|---|---|---|

| Flow wrap | High | Low | High (printed film) |

| Shrink bundling | Medium | Medium | Low |

| Cartoning | Low | High | Medium |

Clients often choose flow wrapping to reduce energy use, speed up operations, and meet retailer shelf-ready requirements. At Hannpro, we’ve helped many factories transition from old-school box-packing to efficient flow wrap multipacks.

Conclusión

Flow wrapping can be both primary and secondary packaging—it all depends on how it’s used. For bundling, it’s a smart secondary solution.