When packing slows down the whole production line, it creates pressure, errors, and waste.

The efficiency of secondary packaging machines lies in their ability to automate labor, cut costs, and maintain a consistent pace of packing operations.

If you want to ship faster, reduce costs, and improve consistency, then upgrading your packaging line with the right equipment might be the smartest decision you can make.

How do secondary packaging machines reduce labor costs?

Packing by hand is slow and unpredictable. It increases errors and makes it hard to meet deadlines.

Secondary packaging machines reduce labor costs by automating tasks like box forming, case packing, and palletizing. This boosts the overall efficiency of secondary packaging machines.

Fewer Workers, More Output

One machine can often replace several workers. A case erector folds boxes faster than any person could. A palletizer stacks with precision all day without getting tired. Automation means I can scale up production without hiring more people or worrying about training, supervision, or sick days.

| Task | Manual Labor (per shift) | With Machine | Result |

|---|---|---|---|

| Box Forming | 2 workers | Case erector | Saved 2 laborers |

| Case Packing | 3 workers | Case packer | Consistent speed and load |

| Palletizing | 2 workers | Robotic palletizer | Improved safety and stacking |

في هانبرو, we’ve helped several customers reduce their packaging team by 40%, allowing them to reallocate those workers to other areas or avoid extra hires during peak seasons. That’s efficiency you can measure in dollars.

How do secondary packaging machines improve consistency and reduce errors?

Manual packing is inconsistent. Each worker does things slightly differently.

The efficiency of secondary packaging machines comes from their precision in sealing, labeling, and loading, which cuts down on errors.

Fewer Mistakes, Better Results

Let’s be honest. Even the best workers get tired or distracted. Machines don’t. They apply tape the same way every time. They fold boxes to the right dimensions. They don’t forget to label a box. This leads to fewer damaged goods and fewer customer complaints.

| Common Error Type | Manual Packing Likelihood | With Machine | Benefit |

|---|---|---|---|

| Improper sealing | عالي | Very low | Better shelf stability |

| Misaligned labeling | Medium | None | Professional presentation |

| Damaged goods in transit | عالي | قليل | Fewer returns and refunds |

One of our Hannpro clients said their return rate dropped by 25% after switching to automated case sealers. That means happier customers and less waste.

Can secondary packaging machines speed up the entire supply chain?

Slow packaging can delay shipping and mess up delivery promises.

Yes, the efficiency of secondary packaging machines allows manufacturers to keep pace with production and meet tight delivery schedules.

Matching Production Pace

When your production line is fast, your packaging line must keep up. Otherwise, products pile up. Machines like wrap-around case packers and robotic arms can handle hundreds of items per minute. That keeps the flow smooth and fast.

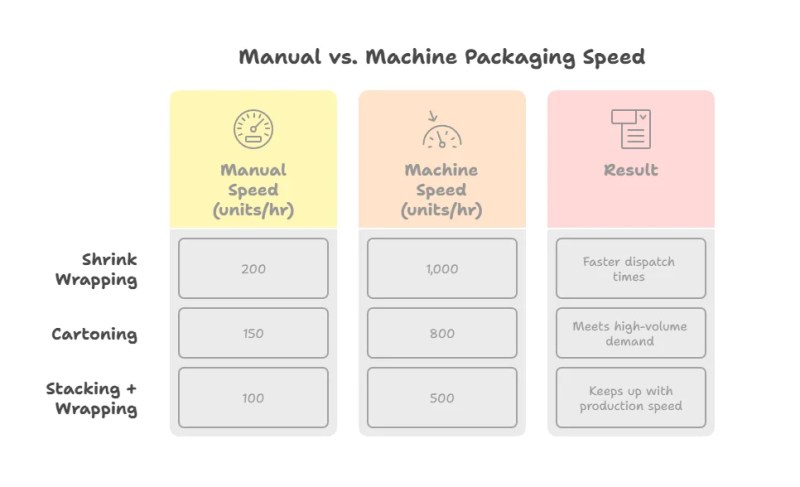

| Packaging Task | Manual Speed (units/hr) | Machine Speed (units/hr) | Result |

|---|---|---|---|

| Shrink Wrapping | 200 | 1,000 | Faster dispatch times |

| Cartoning | 150 | 800 | Meets high-volume demand |

| Stacking + Wrapping | 100 | 500 | Keeps up with production speed |

I remember working with a beverage brand that struggled with packaging delays. We installed a high-speed wrap machine from Hannpro, and they cleared their backlogs in just two days. The line has never slowed down since.

Are secondary packaging machines adaptable to different product types?

Different products need different boxes, wraps, or trays.

Versatility also drives the efficiency of secondary packaging machines, as they support multiple SKUs without constant retooling.

One Machine, Many Uses

You don’t need a new machine for every product. With changeable molds and programmable settings, a single machine can handle a wide range of SKUs. That’s flexibility with no downtime.

| نوع الآلة | Products It Can Handle | How It Adapts |

|---|---|---|

| Case Packers | Bottles, cartons, pouches | Adjustable grippers, trays |

| ماكينات صناعة الكرتون | Blister packs, tubes, jars | Interchangeable feeding systems |

| Shrink Wrappers | Boxes, trays, grouped products | Programmable temperature and speed |

Hannpro machines are designed with quick setup in mind. You just press a button, and it switches modes. That’s ideal if you’re packing multiple product lines in one day.

How do packaging machines reduce material waste?

Packaging waste adds costs and harms the environment.

The efficiency of secondary packaging machines also means optimized material use, reducing tape, film, and cardboard consumption.

Use Only What You Need

Manual sealing often uses too much tape or stretch film. Machines use just enough, every time. That lowers costs and reduces landfill impact. Also, tighter packaging reduces product damage, so you waste fewer goods.

| Material Type | Manual Waste (%) | Machine Waste (%) | Savings |

|---|---|---|---|

| Carton Sealing Tape | 15% | 3% | 12% less per shipment |

| يتقلص الفيلم | 20% | 5% | Longer roll life |

| Stretch Wrap | 18% | 4% | Less material, same grip |

A customer told me they used to go through 20 rolls of tape a day. After installing our Hannpro carton sealer, they only need 12. That’s a 40% drop in tape use, and it adds up.

خاتمة

Efficiency of secondary packaging machines isn’t just a metric—it’s a game changer in cost, time, and quality.

FAQ

1. What is secondary packaging?

Secondary packaging is the layer that groups products for shipping—like boxes, trays, or wrap used to bundle items for transport.

2. How does automation improve packaging efficiency?

Automated machines maintain speed, accuracy, and consistency—ensuring smooth flow and fewer errors.

3. Are secondary packaging machines cost-effective?

Yes. The efficiency of secondary packaging machines means reduced labor, lower material waste, and faster ROI.

4. Do I need a specialist to run the machines?

Most Hannpro machines are user-friendly. We offer training, and most tasks are push-button simple.

5. Is maintenance hard?

Not at all. With basic maintenance schedules and remote support, your line can stay up 99% of the time.

6. Can Hannpro customize a solution for my product?

Absolutely. We specialize in tailor-made solutions to match your product line, output speed, and budget.