Many plants lose time and money in manual packing. Delays grow. Morale drops. Customers wait.

An automatic secondary packaging machine cuts labor cost, raises speed, improves quality, and protects goods. It removes bottlenecks and boosts profit with steady, reliable output.

I used to doubt automation because of the price tag. Then I mapped the hidden costs in our manual line. The gaps were clear. So I switched to an automatic secondary packaging machine. The results changed our daily work. Read on to see how and why.

How does an automatic secondary packaging machine improve efficiency?

Manual packing slows when people get tired or distracted. Errors slip in. Rework grows.

An automatic secondary packaging machine[1] improves throughput and keeps a steady beat. The line moves faster, with fewer stops and less rework.

Where the time goes

I broke down our shift and saw small delays everywhere. People paused to fetch cartons. Tape ran out. Labels jammed. The machine handles these tasks in one flow. It forms, loads, seals, and codes without breaks. This steady rhythm lifts the whole line.

What changes on the floor

| Factor | Before | After |

|---|---|---|

| Carton forming | Manual, slow | Auto, inline |

| Loading | Variable | Timed and guided |

| Sealing | Uneven | Precise and firm |

| Labeling | Off-cycle | In-cycle, verified |

Flow, balance, and uptime

An automatic secondary packaging machine[1] helps me balance upstream and downstream steps. I can match case output to filler speed. I can buffer peaks with conveyors and sensors. The line feels calm. Work gets done.

Why is the total cost of an automatic secondary packaging machine lower?

Upfront price looks high. Daily labor looks cheap. This is the trap.

Total cost of ownership favors an automatic secondary packaging machine because labor, waste, returns, and downtime shrink. The machine pays back and then keeps saving.

Seeing the full picture

I list all costs for five years, not five weeks. I add wages, overtime, turnover, hiring, training, rework, tape waste, film waste, damaged goods, returns, and chargebacks. With an automatic secondary packaging machine, many of these costs vanish.

Cost map (5-year view)

| Cost Bucket | Manual Line | Automated Line |

|---|---|---|

| Direct labor | High and rising | Much lower |

| Material waste | Frequent | Minimal |

| Returns/damages | Costly | Rare |

| Maintenance | Low but chaotic | Planned and steady |

| Lost sales | Hidden but real | Lower risk |

Cash flow and payback

Savings begin on day one because labor and waste drop at once. When energy prices rise or labor gets tight, the automatic secondary packaging machine looks even better.

Can an automatic secondary packaging machine improve product safety?

Weak seals and crooked cases lead to damage. That hurts trust.

An automatic secondary packaging machine improves protection with uniform forming, accurate loading, and controlled sealing and wrapping.

What quality really needs

Quality is not only nice tape lines. It is correct case size, right compression, proper overlap, and verified labels. With an automatic secondary packaging machine, these steps repeat perfectly every time.

Protection checklist

| Item | Manual Risks | Automated Controls |

|---|---|---|

| Case square | Off-angle | Squaring bars |

| Fill ratio | Under/over | Weight checks |

| Seal strength | Inconsistent | Measured pressure |

| Label accuracy | Misplaced | Vision system |

The ripple in logistics

Better cases stack better. Pallets stay stable. Trucks load faster. With an automatic secondary packaging machine, complaints and returns drop. Customers notice the difference.

Does an automatic secondary packaging machine help with scalability?

Demand changes. Manual lines struggle to scale up or down fast.

An automatic secondary packaging machine scales with simple schedule changes and tool-less changeovers. It handles more SKUs without hiring rushes.

When orders spike

With manual packing, a surge means late shifts, temp hires, and training stress. With automation, I just adjust schedules. No extra hiring.

Scale and flexibility grid

| Dimension | Manual | Automated |

|---|---|---|

| Throughput | People-bound | Program-bound |

| Changeover | Slow, tribal | Guided, quick |

| SKU count | Hard to grow | Easier to grow |

| Crew size | Must rise | Can stay flat |

SKU variety without chaos

An automatic secondary packaging machine stores recipes for each SKU. Adjustable rails and auto label updates keep the line synced. This makes small batch runs profitable.

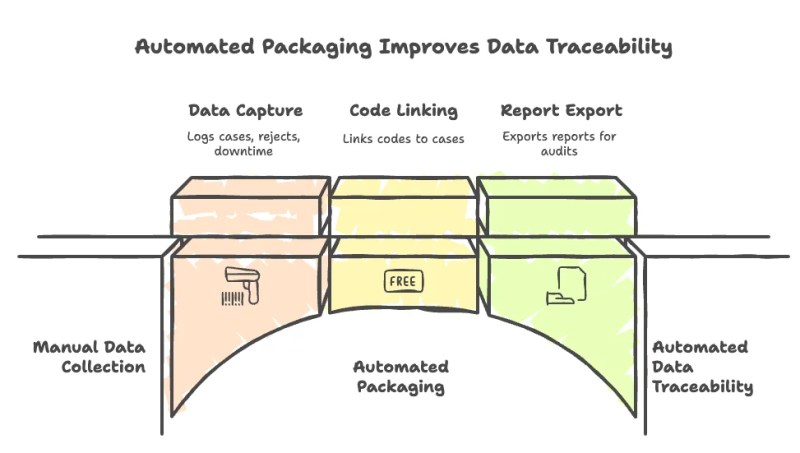

What about data, traceability, and compliance?

Audits demand proof. Manual notes are messy.

An automatic secondary packaging machine captures data at the source, links codes to cases, and exports reports for audits and customers.

Data that tells the truth

It logs cases per hour, reject reasons, downtime codes, and label verifications. Lot and shift tags help with traceability.

Data layer snapshot

| Data Point | Use | Value |

|---|---|---|

| Case count | OEE | Capacity planning |

| Reject code | QA | Root-cause action |

| Label verify | Compliance | Fewer fines |

| Lot link | Traceability | Faster recalls |

Standards and partners

With an automatic secondary packaging machine, data flows cleanly into ERP and WMS. This means faster audits, fewer disputes, and happier partners.

How do I choose the right automatic secondary packaging machine?

Choice is hard. Specs look similar.

I match needs to line speed, case mix, space, and budget before I buy an automatic secondary packaging machine.

Fit before finish

I measure the space. I check infeed height, outfeed height, and traffic flow. I list the top SKUs. I time my upstream process. Then I choose.

Selection map

| Area | Questions | Why it matters |

|---|---|---|

| Speed | Peak vs. average? | Avoid bottlenecks |

| SKUs | Sizes and changeover? | Keep flexibility |

| Space | Footprint and access? | Safe service |

| Service | Local parts, techs? | Fast recovery |

Trials and service plan

I send samples and test cases. I plan spare parts and preventive maintenance[2] early. With the right automatic secondary packaging machine, launch is smooth and ROI[3] is faster.

What ROI can I expect?

Leaders want numbers. Teams want proof.

ROI from an automatic secondary packaging machine comes from labor savings, reduced waste, fewer returns, and more throughput.

The math I use

I keep it simple and honest. I use base, upside, and downside scenarios. I track results after install to confirm payback.

ROI sheet (example)

| Input | Manual | Automated |

|---|---|---|

| Cases/shift | 4,000 | 8,000 |

| Labor/shift | 8 people | 3 people |

| Scrap rate | 3% | 0.8% |

| Damage/returns | 1.5% sales | 0.3% sales |

Decision with confidence

This model makes the case clear. The automatic secondary packaging machine proves its value month after month.

Conclusion

An automatic secondary packaging machine saves time, cuts cost, protects goods, scales fast, and proves results with data.

[1]: Explore the advantages of automation in packaging to enhance efficiency and reduce costs.

[2]: Explore the maintenance needs of automated systems to ensure smooth operation.

[3]: Get insights into the return on investment from implementing automated packaging.