Packaging delays? Product damage? Too many workers on the line? These are common headaches before automating with a cartoning machine.

The operation of cartoning machine involves forming cartons from flat blanks, inserting products inside, and sealing the cartons automatically with high speed and accuracy.

Before I started manufacturing cartoning machines, I had no idea how much time and money companies were wasting on manual packaging. In this post, I’ll explain the full operation of cartoning machine—from start to finish—so you can understand its value and know what features to look for.

What is a cartoning machine?

Machines save labor. But how exactly do they do that in packaging?

A cartoning machine is an automated system that forms, fills, and seals cartons, allowing products to be packaged efficiently and neatly.

Types of Cartoning Machines

There are two main types used in the operation of cartoning machine systems: horizontal and vertical.

| Type | How it works | Suitable for |

|---|---|---|

| Horizontal Cartoner | Product is pushed sideways into the carton | Bottles, tubes, flow-wrapped products |

| Vertical Cartoner | Product is dropped from the top into the carton | Sachets, granules, small items |

This classification helps companies choose the right cartoning machine operation mode based on the product type.

How does a cartoning machine form the carton?

Boxes come flat. So how do machines turn them into cartons?

The forming section of the cartoning machine operation uses vacuum suction and mechanical arms to pull, open, and shape flat blanks into upright cartons.

Carton Forming in Steps

The forming station is the first phase in the operation of cartoning machine systems.

| Step | Description |

|---|---|

| 1. Blank Picking | Vacuum arm grabs flat cartons from stack |

| 2. Carton Opening | Suction cups pull open the carton sides |

| 3. Shaping and Lock | Mechanical arms lock it into rectangular shape |

| 4. Transfer to Load | Moves formed carton to next station |

Carton forming is the foundation of the entire cartoning machine operation. Precision at this stage reduces jamming and increases speed.

How does the machine fill the product into the carton?

It sounds simple, but precision is everything when filling cartons.

In the operation of cartoning machine systems, the product is inserted into the open carton using pushers, gravity, or robotic arms.

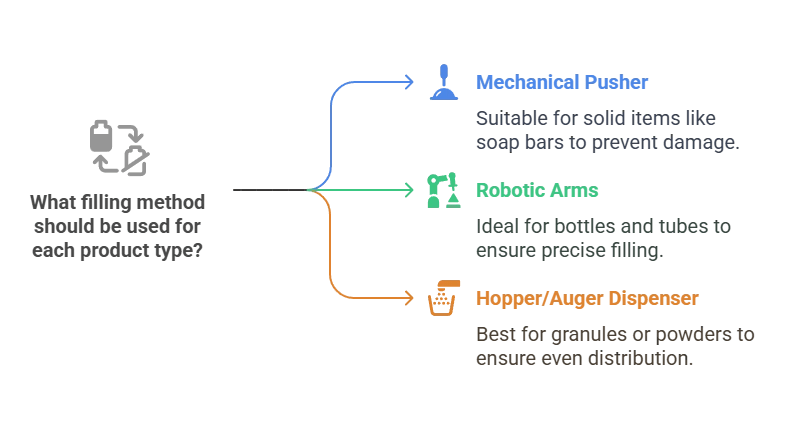

Filling Variations by Product Type

Each product needs a matching filling technique to avoid damage or misplacement.

| Product Type | Filling Method |

|---|---|

| Solid items (soap bars) | Mechanical pusher inserts item |

| Bottles/Tubes | Robotic arms or pushers |

| Granules/Powders | Hopper or auger dispenser |

During machine tests, we saw that even a 2mm misalignment could cause a misfeed. We corrected that with adjustable guiding tracks in our Hannpro models—one small tweak, big difference.

How is the carton sealed?

Once filled, the box has to close securely. Here’s how that happens.

The final step in the operation of cartoning machine systems involves sealing the carton using either tuck-in flaps or hot melt glue.

Sealing Techniques Compared

Sealing is essential for both appearance and product protection.

| Sealing Type | Process | Best For |

|---|---|---|

| Tuck-in Flaps | Flaps are folded and pushed into position | Lightweight or display products |

| Hot Melt Glue | Glue applied, then pressure-sealed | Heavy items, long-distance shipping |

Glue sealing is more secure and is often chosen for international shipments. That’s based on feedback from clients shipping food abroad.

Can cartoning machines integrate with upstream and downstream systems?

A machine alone isn’t enough—it has to work in a line.

Yes, part of the operation of cartoning machine equipment is the ability to integrate with conveyors, leaf inserters, and case packers.

Integration Possibilities

System integration is a big part of modern packaging automation.

| Machine Connected | Purpose |

|---|---|

| Conveyor from filler | Delivers product into cartoner |

| Leaflet inserter | Adds instructions into cartons |

| End-of-line packer | Packs sealed cartons into boxes |

We designed a full line for a cosmetics client, including QR code printers, insert loaders, and final box stackers—all synced with the cartoner.

How does a cartoning machine handle errors or misfeeds?

No machine is perfect, but some handle errors better than others.

Error management is built into the operation of cartoning machine systems, with sensors and ejectors ensuring continuous and safe performance.

Smart Features for Error Handling

These features prevent long downtimes.

| Sensor Function | What It Detects |

|---|---|

| Carton presence sensor | Checks if carton is properly placed |

| Product detection sensor | Confirms product is loaded correctly |

| Ejector mechanism | Removes faulty cartons |

We added an auto-eject feature after one client requested zero manual intervention. That small change saved hours of manual inspection.

How fast is a cartoning machine?

Speed matters when you’re scaling production.

The operation of cartoning machine equipment varies in speed from 40 to 300 cartons per minute depending on model and product type.

Speed by Industry Example

Different industries require different speeds.

| Industry | Cartons/Minute | Machine Type |

|---|---|---|

| Pharmaceuticals | 60–120 | Vertical cartoner |

| Food & Snacks | 100–300 | Horizontal cartoner |

| Cosmetics | 40–80 | Robotic-assisted |

This is why we always ask clients about their daily volume goals before recommending a specific machine.

Conclusion

The operation of cartoning machine systems simplifies and accelerates packaging by automating carton forming, filling, and sealing.